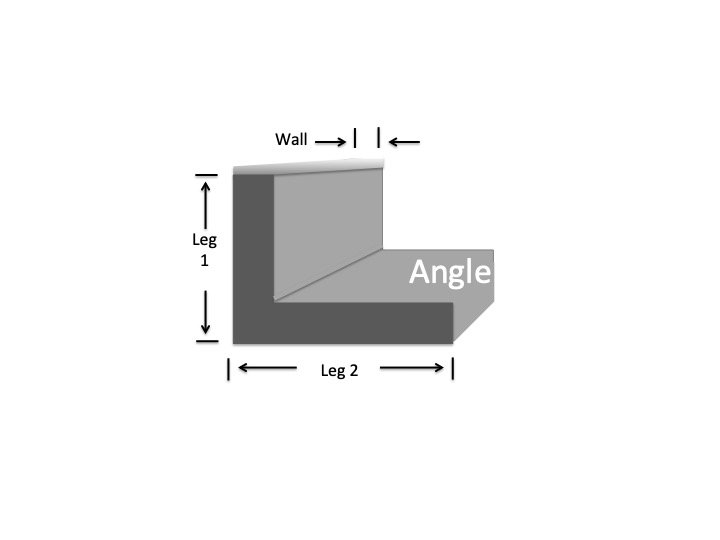

6061 aluminum angle is the most commonly used aluminum for structural applications. It has above average corrosion resistance, good machinability, and is excellent for welding. 6061 aluminum angle is heat-treatable, resistant to stress cracking and non-magnetic.

6061-T6 Angle features rounded corners and approximately twice the strength of 6063-T52 Angle.

Reviews

There are no reviews yet.